| Availability: | |

|---|---|

| Quantity: | |

ZSXCD-888

ZEUS

ZSXCD-008

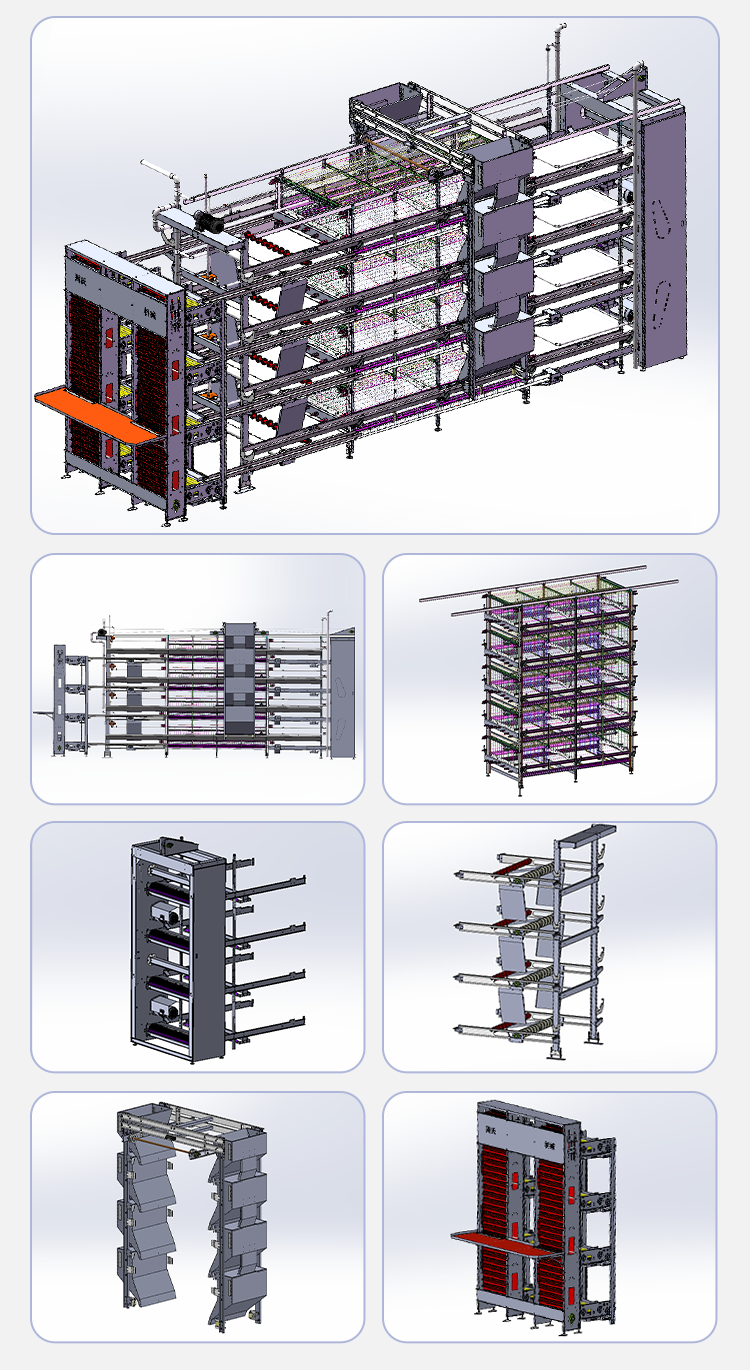

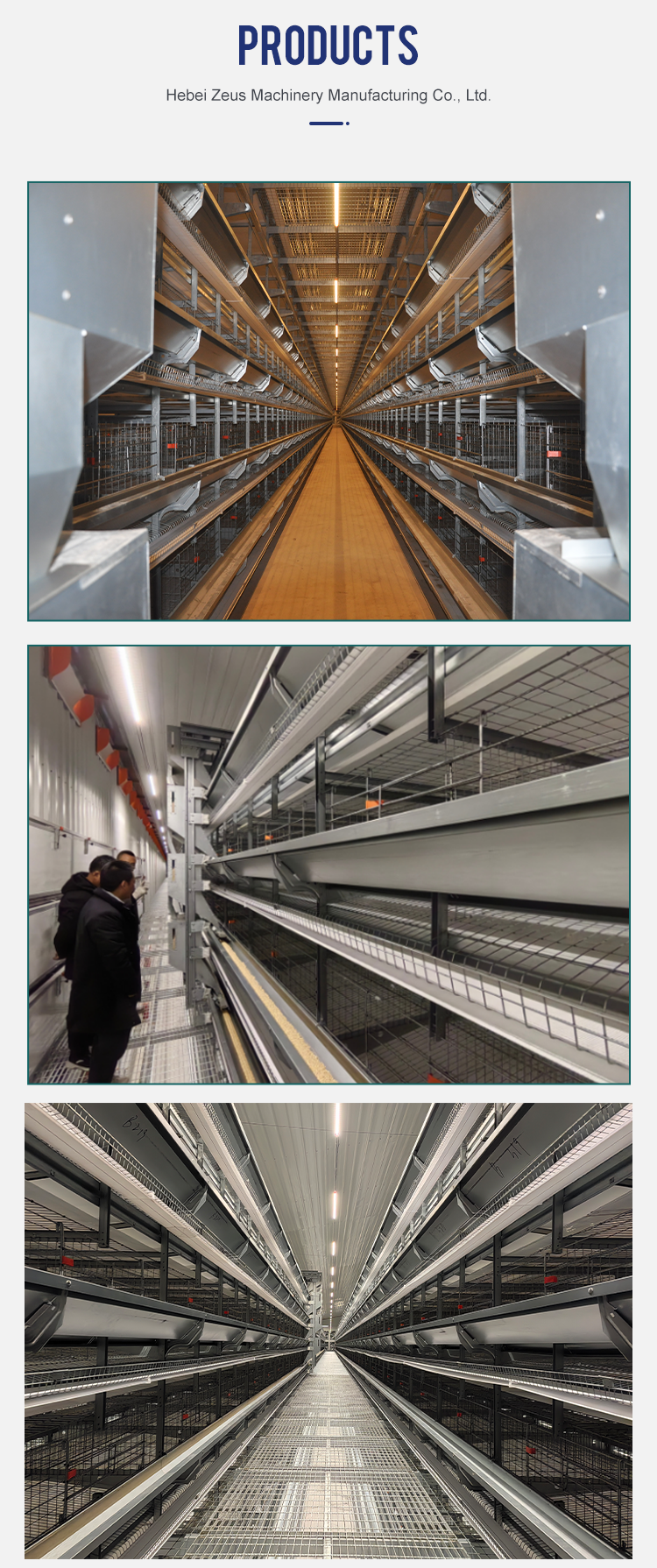

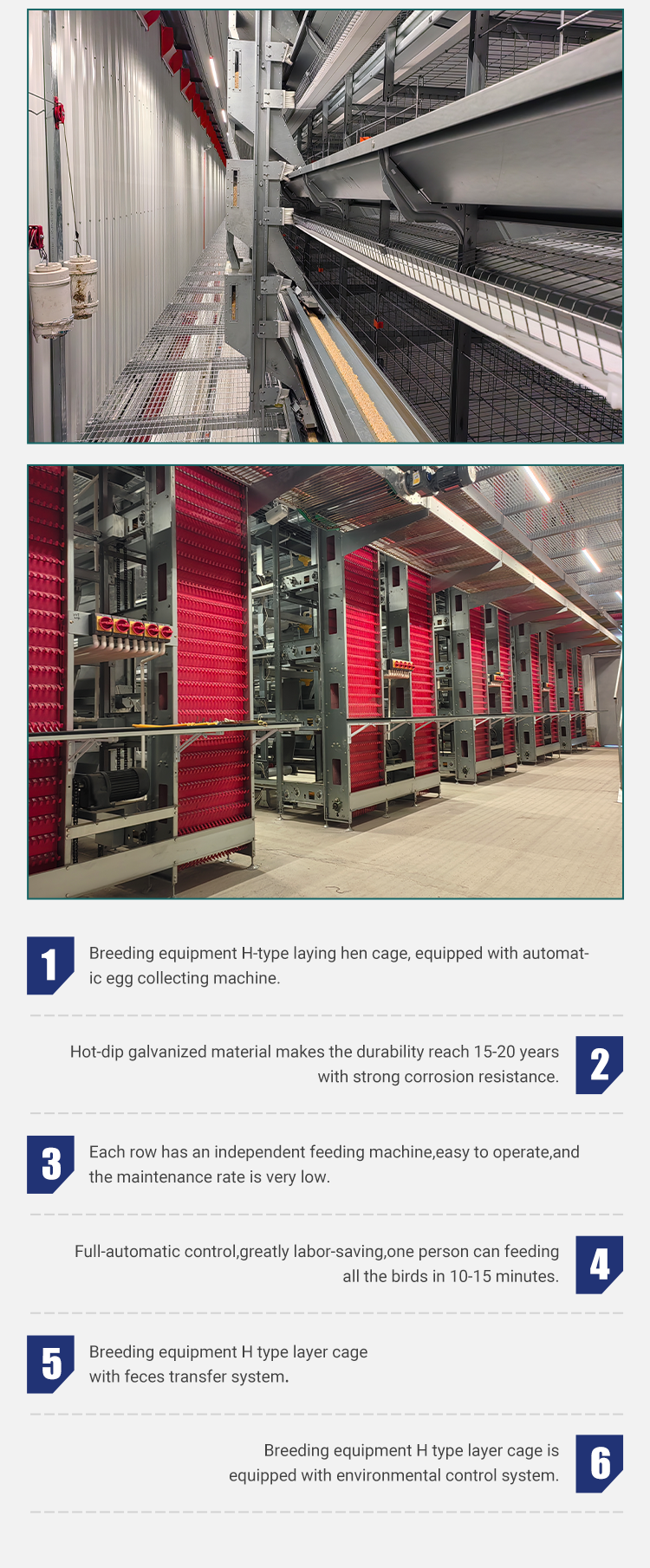

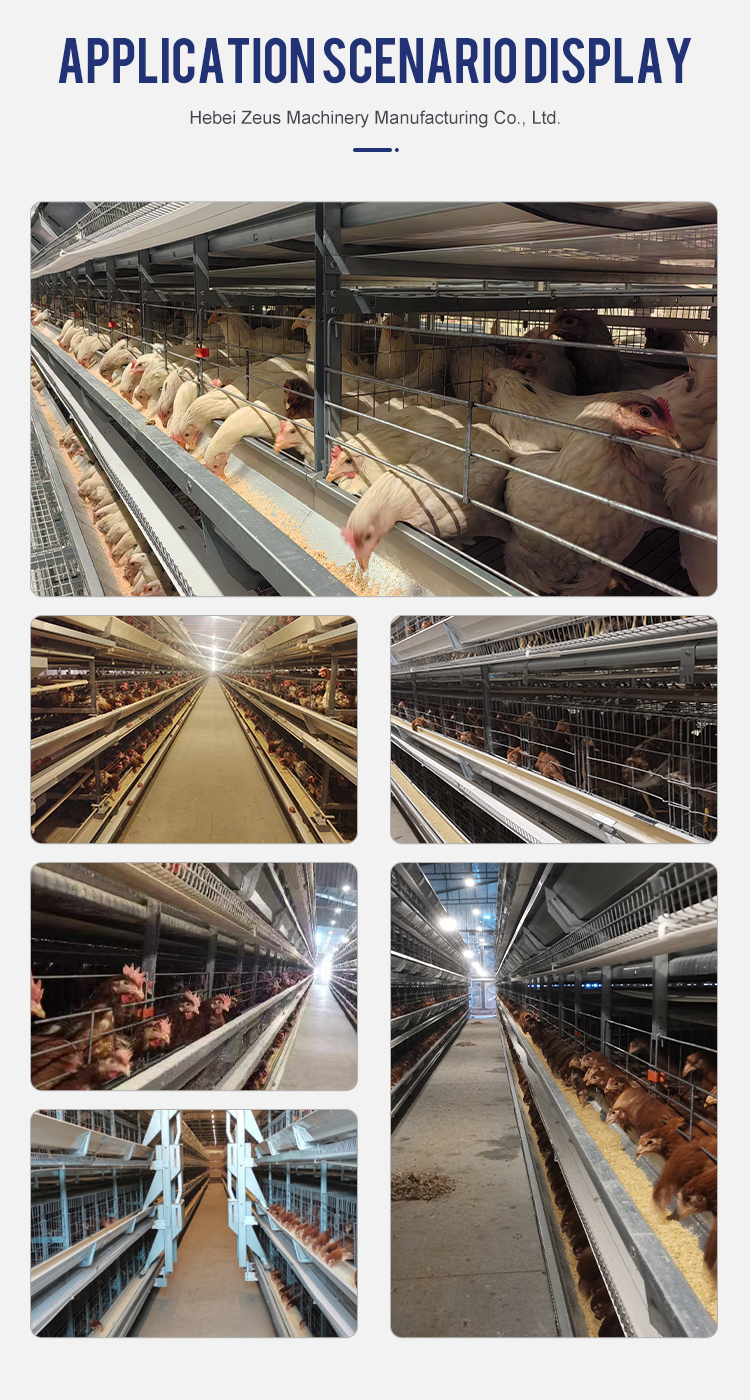

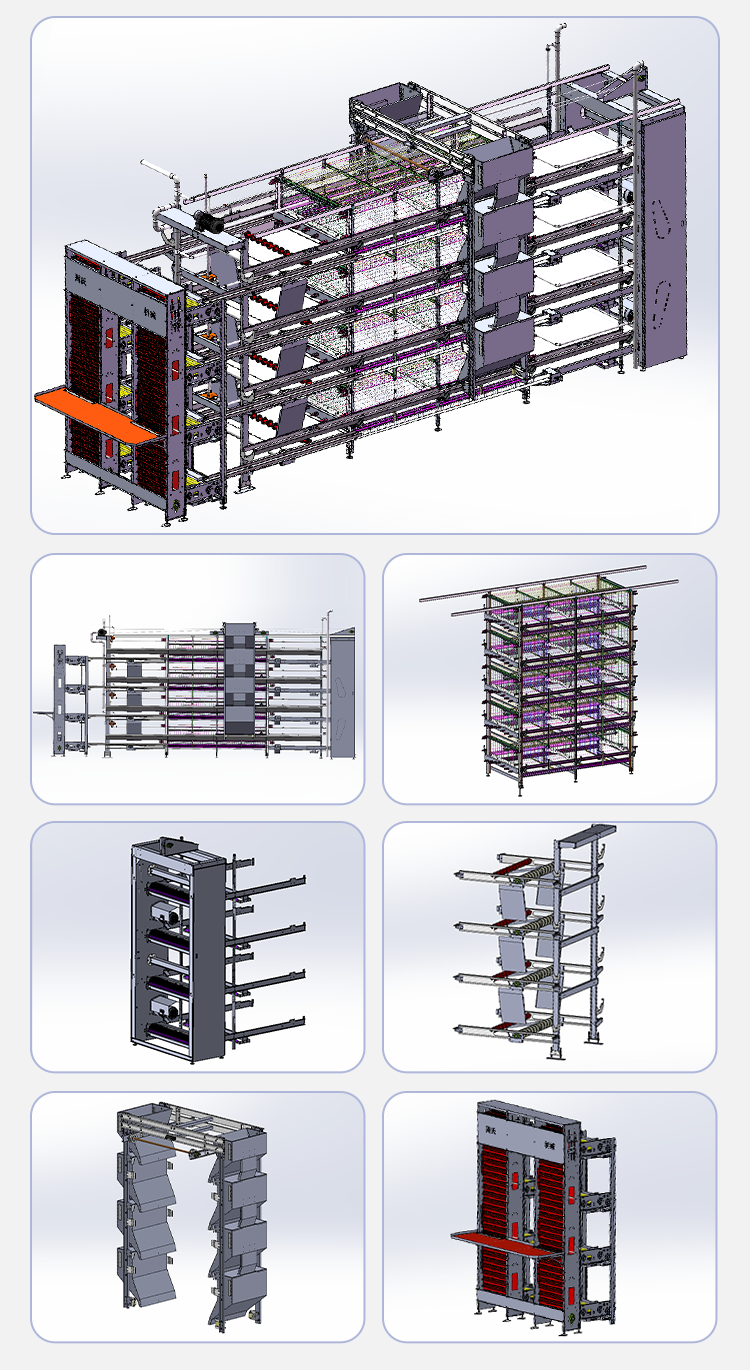

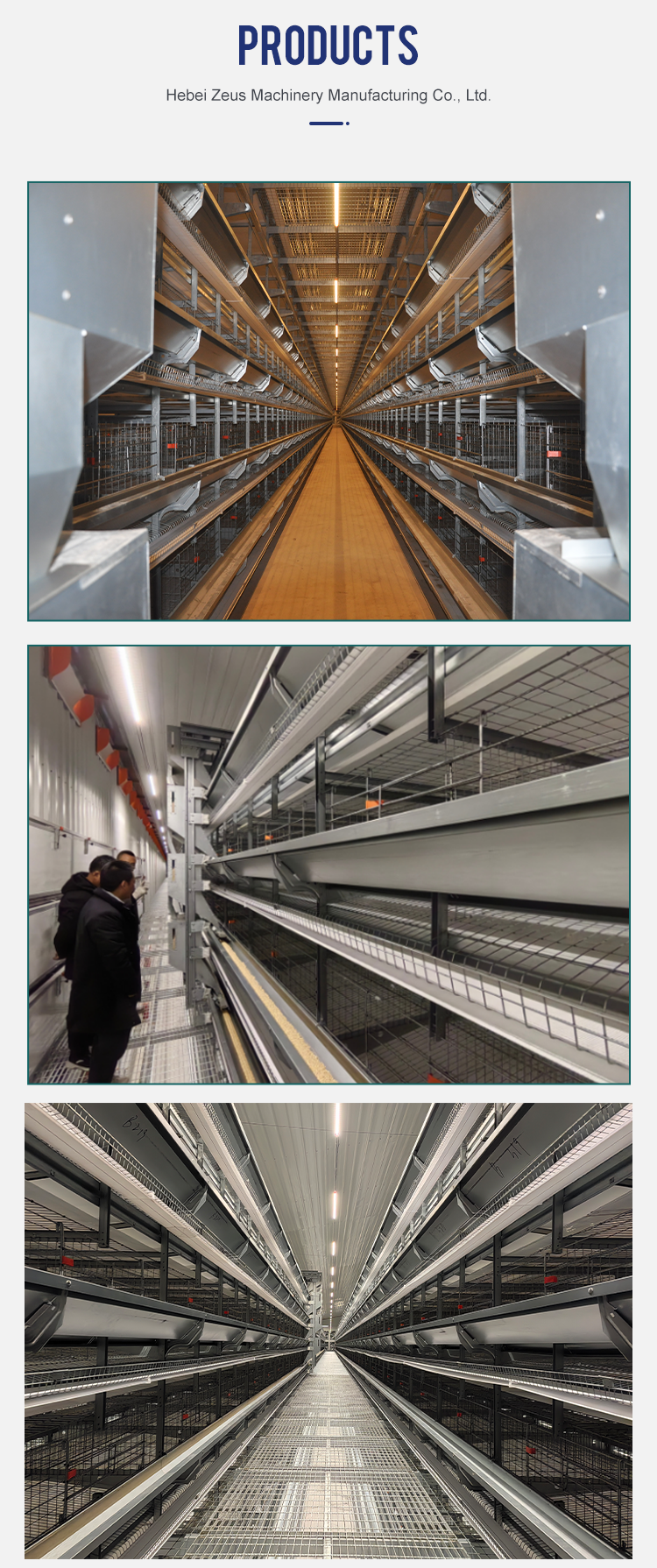

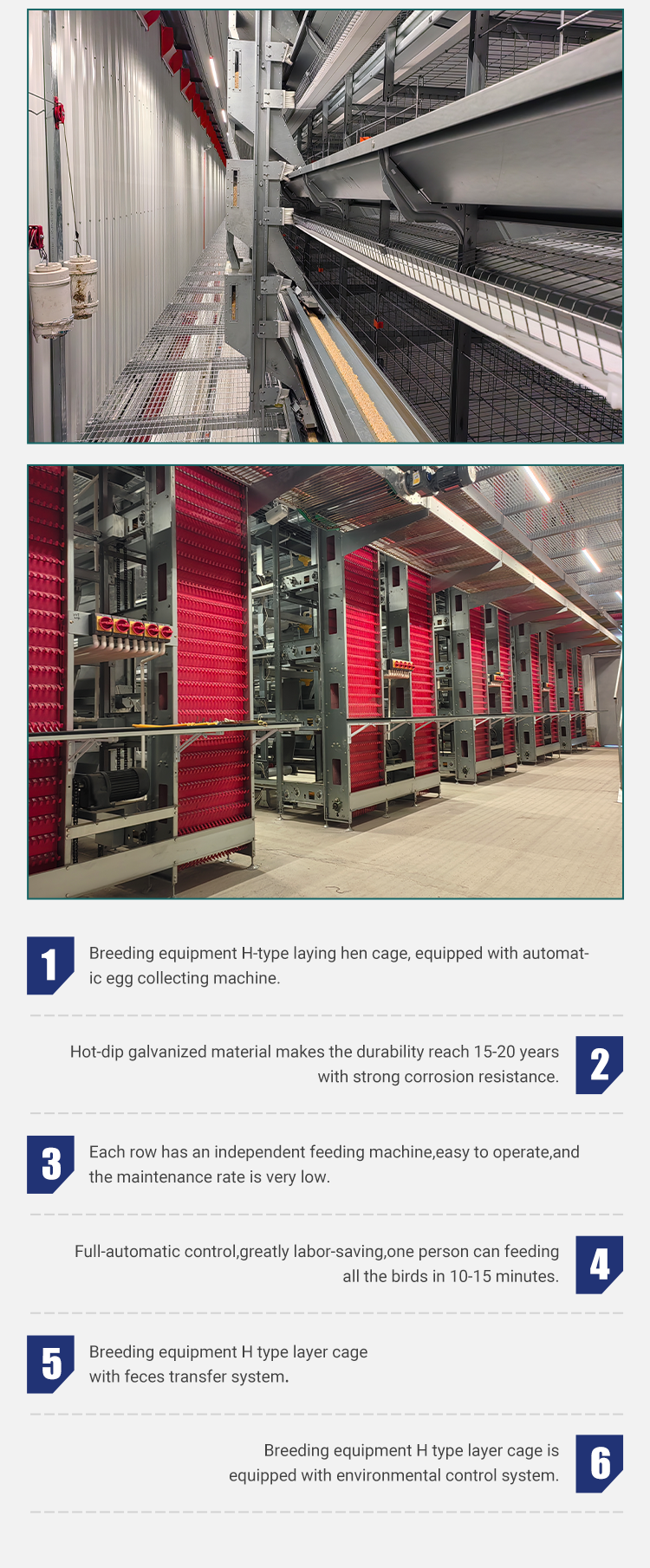

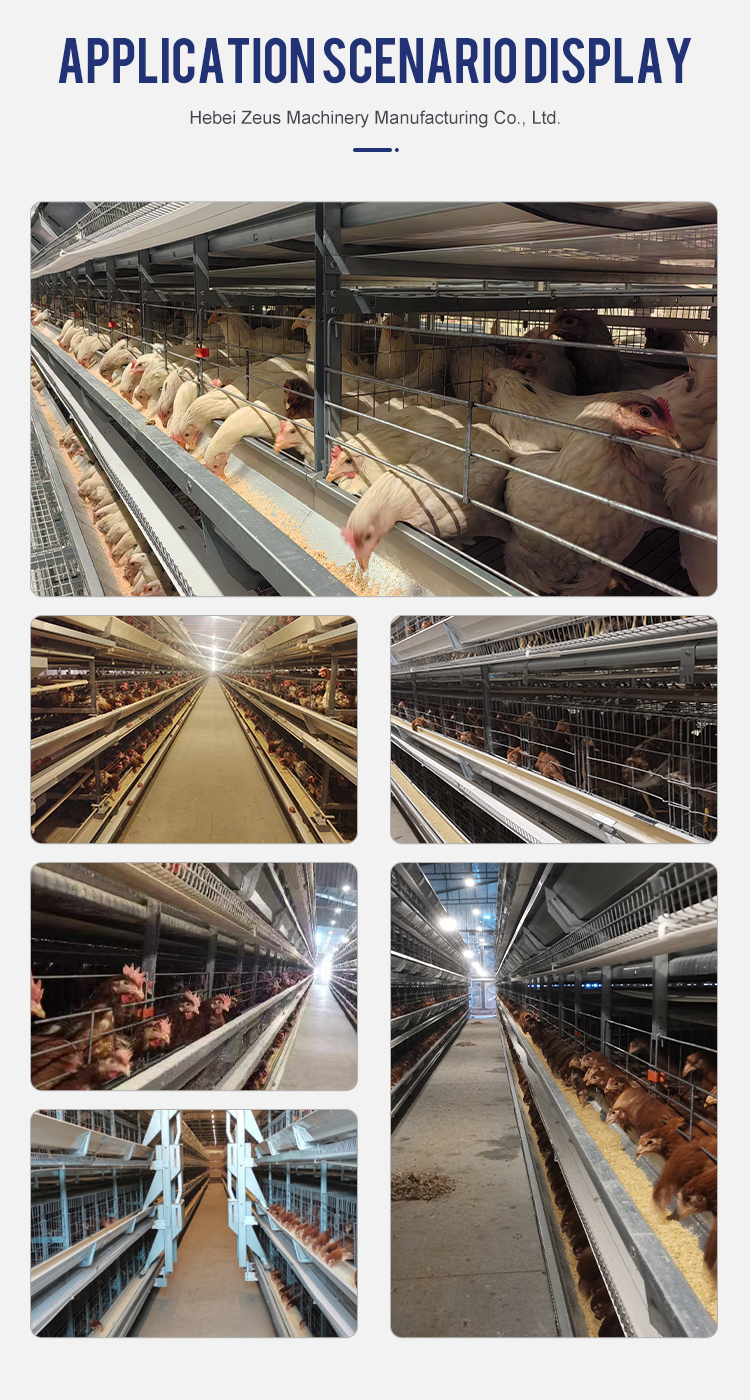

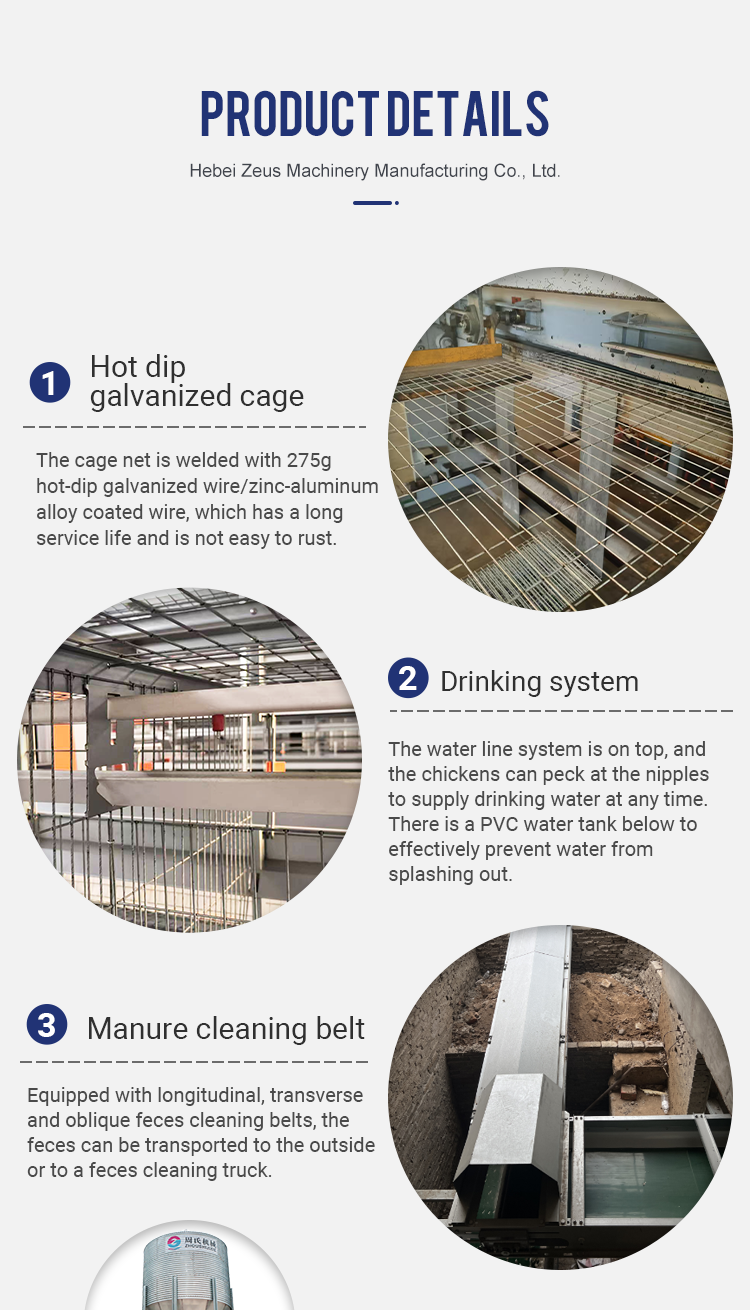

The H-type cascading laying hen automated breeding system can be designed with 3-12 layers according to customer needs. The system includes egg collection, feeding, drinking water, manure cleaning, lighting, environmental control and other modules to meet the user's highest requirements in terms of animal health, egg production performance and environmental factors.

●The laminated frame features a reasonable design and a firm and reliable structure. High-densityfeeding saves land and cost.

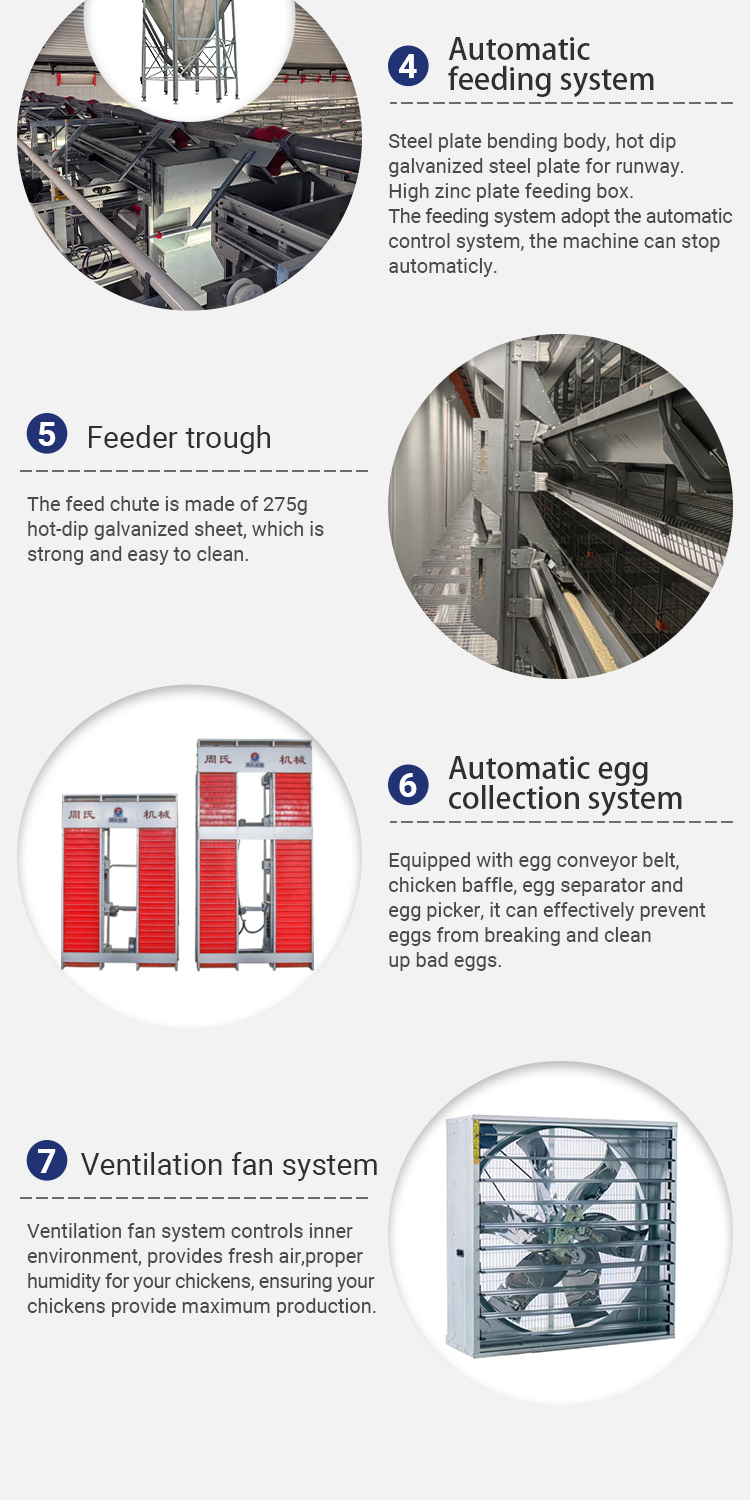

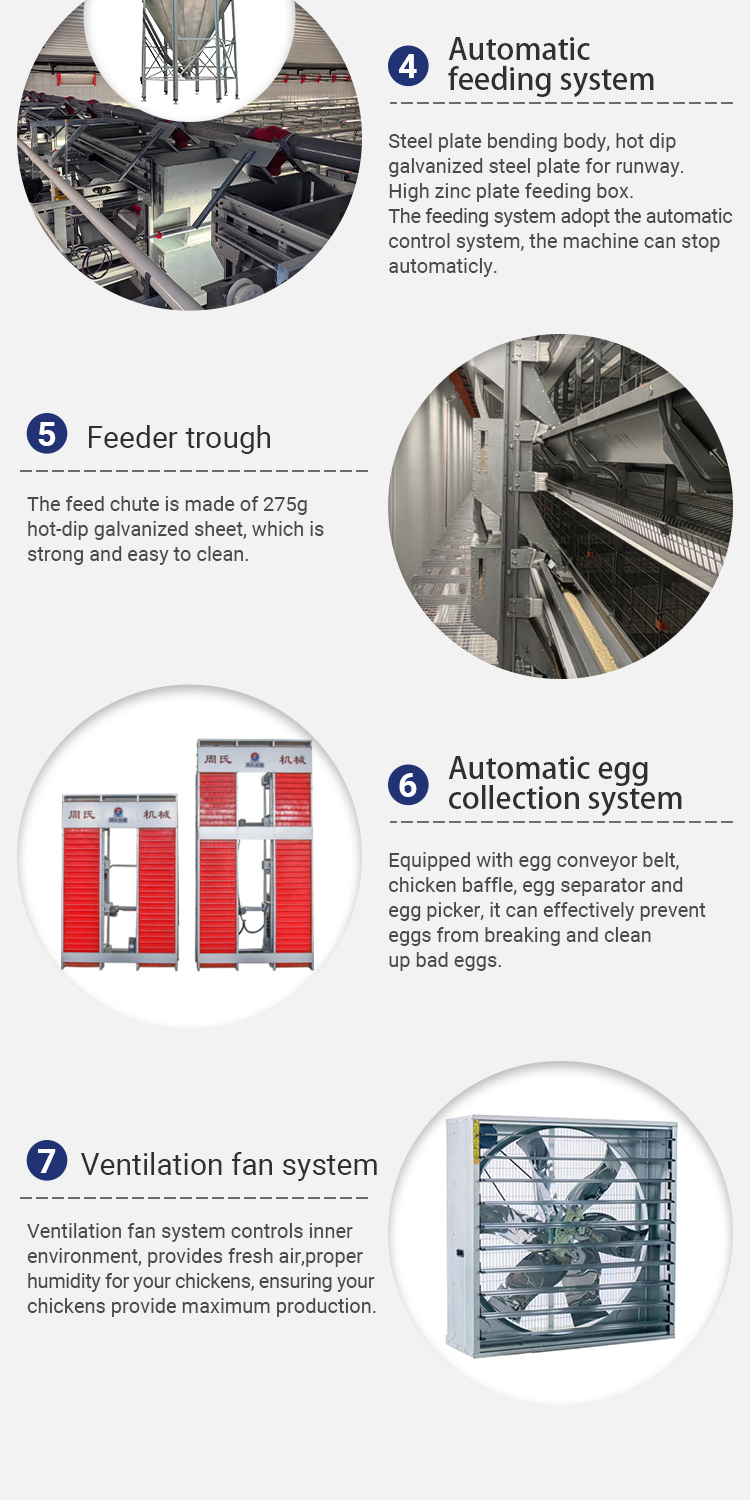

●The egg collection system features stable operation, low egg breaking rate, convenient operation

and high automation.

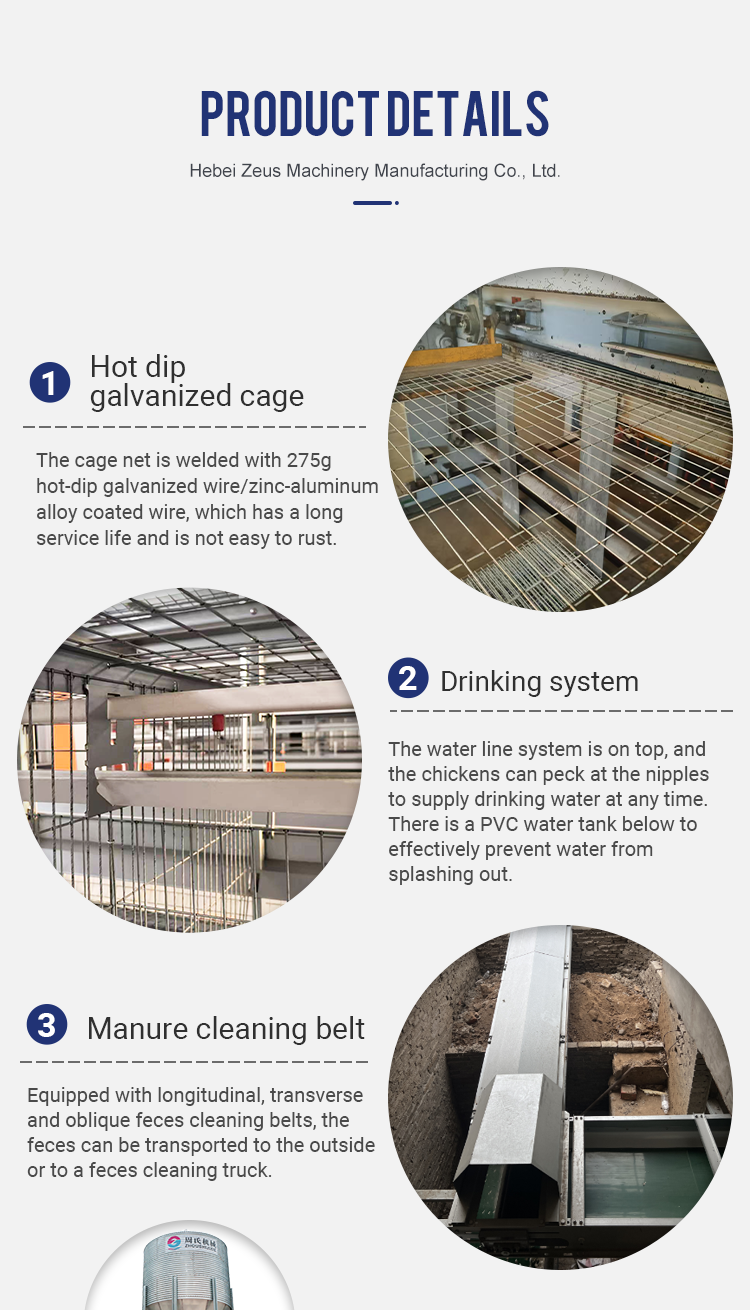

●The front-end filter unit ensures clean water, with 2 nipples in a single cage, sufficient watersupply and convenience in drinking.

●The manure cleaning system features high resistance to corrosion and reasonable structuraldesign, ensuring that the manure belt is clean.

●The climate control system is highly automated and inteligent, providing a good livingenvironment for birds, which can reduce mortality rate of birds and enhance laying rate.

●All cage system is made of hot galvanized plate, strong corrosion resistance.

●All mesh are made of aluminum plated zinc wire welding, corrosion resistance is 3-4 times of normal hot dip galvanized wire mesh,long service life.

●The structure of sliding cage door facilitates operation and prevent birds removing.

●V-shaped rolled feed trough has high structural strength and wide section, saving feed, preventing feed throwing and mildew, andimproving feed conversion rate.

●Reasonable Angle of bottom net, ensure that eggs roll to the egg belt smoothly, effectively reduce the rate of egg damage.

●A V-shaped water trough is arranged under the drinking line to prevent water drops from falling on the manure belt, and the watercontent of birds manure is low.

The H-type cascading laying hen automated breeding system can be designed with 3-12 layers according to customer needs. The system includes egg collection, feeding, drinking water, manure cleaning, lighting, environmental control and other modules to meet the user's highest requirements in terms of animal health, egg production performance and environmental factors.

●The laminated frame features a reasonable design and a firm and reliable structure. High-densityfeeding saves land and cost.

●The egg collection system features stable operation, low egg breaking rate, convenient operation

and high automation.

●The front-end filter unit ensures clean water, with 2 nipples in a single cage, sufficient watersupply and convenience in drinking.

●The manure cleaning system features high resistance to corrosion and reasonable structuraldesign, ensuring that the manure belt is clean.

●The climate control system is highly automated and inteligent, providing a good livingenvironment for birds, which can reduce mortality rate of birds and enhance laying rate.

●All cage system is made of hot galvanized plate, strong corrosion resistance.

●All mesh are made of aluminum plated zinc wire welding, corrosion resistance is 3-4 times of normal hot dip galvanized wire mesh,long service life.

●The structure of sliding cage door facilitates operation and prevent birds removing.

●V-shaped rolled feed trough has high structural strength and wide section, saving feed, preventing feed throwing and mildew, andimproving feed conversion rate.

●Reasonable Angle of bottom net, ensure that eggs roll to the egg belt smoothly, effectively reduce the rate of egg damage.

●A V-shaped water trough is arranged under the drinking line to prevent water drops from falling on the manure belt, and the watercontent of birds manure is low.